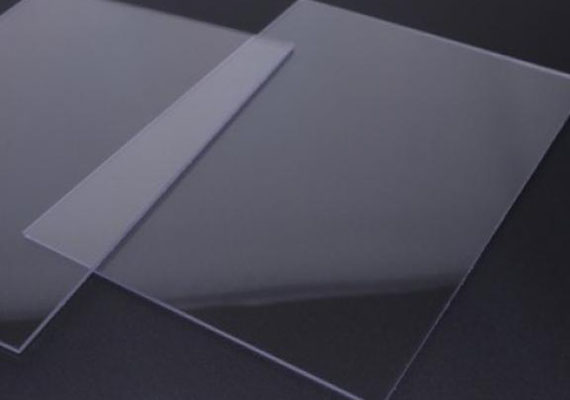

Polycarbonate (PC) an ƙirƙira shi a cikin takaddama mai laushi ta hanyar aikin extrusion. A cikin tsarin extrusion, polycarbonate ana ci gaba tare da dunƙulewa ta yankin zafin jiki da matsin lamba inda aka narkar da shi kuma aka matse shi, kuma a ƙarshe aka tilasta shi ta hanyar siffa mai mutuwa. PC za a iya extruded cikin daban-daban kauri: 0.25mm, 0.5mm, 0.7mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm da 2.0mm. Kaurin da aka saba amfani da shi shine 0.5mm, 0.7mm, 0.8mm da 1.0mm.

Za'a iya haɗa PC tare da launuka daban-daban don samun haske, haske, gani da haske.

Screw extruder za a iya amfani daban-daban irin zane don ƙirƙirar irin zane PC sheet.

Coextrusion PC / PMMA. Films ko zanen gado suna ɗauke da yadudduka na polymer biyu ko fiye daban waɗanda za a iya samarwa ta hanyar haɗuwa da narkakkun rafuka. Ana iya amfani da wannan aikin don haɗa abubuwa don samar da haɗin kaddarorin da ba za a iya samu a cikin polymer ɗaya ba.

Vacuum kafa PC na iya samar da kariya ta tasiri kamar yadda kwanyar ke kare kwakwalwa.

Vacuum kafa PC na iya zama zamiya mai launi don ƙirƙirar aikin MIPS don gudanar da tasirin tasirin juyawa.

Thermoforming sanannen tsari ne na kera kwalkwali, wanda ke sanya takardar polycarbonate mai launin silks a cikin tanda don preheat, sanya polycarbonate a cikin injin buhu, takardar tana zafin jiki zuwa zafin jiki mai sassauci, wanda aka kirkira zuwa takamaiman fasali a cikin sifa, fasalin samfuran daban. kuma tsayi zai haifar da bambance-bambance iri daban-daban yayin samarda buyayyar wuri, mafi karancin wuri ya kafa PC mafi hatsarin launi fadeaway ko rage karfin hular kwano, saboda haka yana da mahimmanci ayi nazari da zaban kaurin takardar polycarbonate daidai wanda yake da dangantaka da ingancin hular kwano da gwajin tasiri. kuma an gyara shi don ƙirƙirar samfurin amfani.

Kafin tsarin samar da injin, munyi amfani da wani layin kare fim akan takardar polycarbonate bayan extrusion, fim din yana kare Polycarbonate daga karce lokacin EPS a cikin-gyare-gyare, kuma cire fim mai kare lokacin taron hular kwano na ƙarshe.

PC PMMA mai haɗawa

PC mai haske

Madubi Tantancewar PC

PC ɗin rubutu

PC mai kyalli